China PCB Board/PCB Assembly Apply for Electronic Products

China PCB board/PCB assembly apply for electronic products WELCOME TO XJY--------------- Shenzhen Xinjiaye Electronics T;

Basic Info

| Model NO. | XJY-PCB 147 |

| Production Process | Subtractive Process |

| Base Material | Fr4 |

| Insulation Materials | Organic Resin |

| Surface Finishing | Hal, HASL Lead Free, Immersion Gold, G |

| Copper Thickness | 1oz |

| Board Thickness | 1.6mm |

| Min. Hole Size | 0.2mm |

| Min.Line Wigth | 0.2mm |

| Min. Line Spacing | 0.2mm |

| Layer | 1 to 24 |

| Solder Mask | Green,Blue,Ect |

| Legend Mask | White |

| Certificate | UL,SGS,RoHS,ISO 9001 |

| Transport Package | Vacuum Package |

| Specification | Normal |

| Trademark | XJY |

| Origin | China |

| HS Code | 85340090 |

| Production Capacity | 5000 Square Meter/Square Meters / Month |

Product Description

China PCB board/PCB assembly apply for electronic productsWELCOME TO XJY---------------

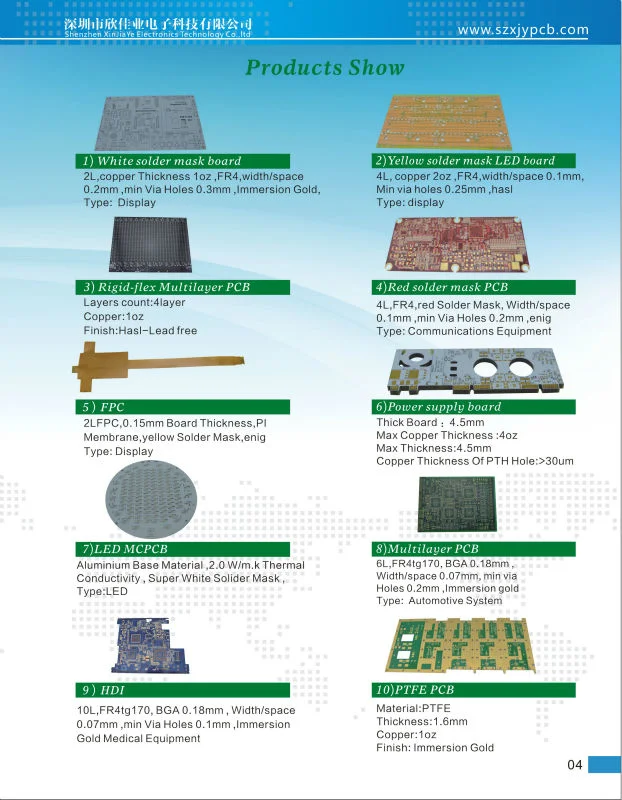

Shenzhen Xinjiaye Electronics Technology is a professional pcb manufacturer has over 10 years experience. We are able to offer 1 to 24 Layer PCB, ranging from pcb produce, components purchase, pcb assembly, pcb copy service.Our products are widely used in communication apparatus, automobile electronics, auto parts, computers, medical devices, light systems, outdoor systems, network devices and consumer electronics class fields.

++++++++Quick Details

Place of Origin: | Guangdong China (Mainland) | Brand Name: | XJY | Model Number: | xjy-pcb 147 |

Base Material: | FR4 | Copper Thickness: | 0.5-3OZ | Board Thickness: | 1.6mm |

Min. Hole Size: | 0.2mm | Min. Line Width: | 0.2mm | Min. Line Spacing: | 0.2mm |

Surface Finishing: | HAL, HASL Lead Free, Immersion gold, Gold plating, Gold finger, immers |

Our PCB board manufacture

* PCB board file with parts list provided by customers

* PCB board made, circuit board parts purchased by us

* Electronic testing circuit board

* Fast delivery, anti-static package

* RoHS Directive-compliant, lead-fre

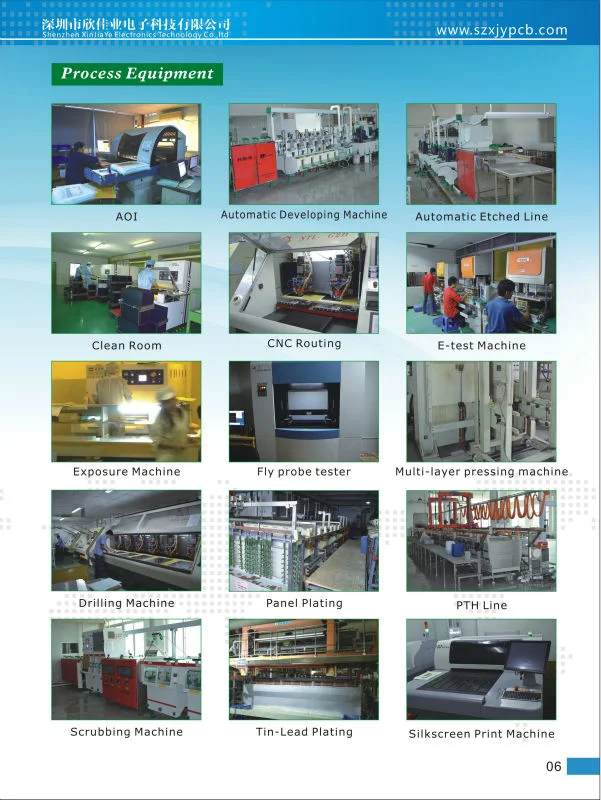

Technology capability

Items | Single/Double-sided Board/Multilayer Board/FPC(1-24Layer) | ||

| Base Materials | FR-4(High TG 150°-170°),FR1,Aluminum,CEM-3,BT,94vo | ||

| Finish copper thickness | Outer 6 OZ,Inner 4 OZ | ||

| Surface finish | ENIG, ImAg, ImSn, OSP, HASL,Plating gold | ||

| Finished Board Size | Max Double-sided Board | 640mm χ 1100mm | |

| Max Multilayer Board | 640mm χ 1100mm | ||

| Finished Board Hole Size (PTH Hole) | Min Finished Board Hole Size | 0.15mm | |

| Conductor Width and Spacing | Min Conductor Width | 0.01mm | |

| Min Conductor Spacing | 0.01mm | ||

| Thickness of Plating and Coating Layer | PTH Wall Copper Thickness | >0.02mm | |

| Tin Solder Thickness ( Hot Air Leveling ) | >0.02mm | ||

| Nickl/Gold Thickness | For customer special need | ||

| Nickl Plating Layer | >2um | ||

| Gold Plating Layer | >0.3um | ||

| Bare Board Test | Single Side Test | Max Test Point | 20480 |

| Max Board Test Size | 400mm χ 300mm | ||

| Double Side Test | Max Test Point | 40960(General Use) | |

| 4096(Special Use) | |||

| Max Board Test Size | 406mm χ 325mm | ||

| 320mm χ 400mm | |||

| Min Test pitch of SMT | 0.5mm | ||

| Test Voltage | 10-250V | ||

| Mechanical Process | Chamfer | 20°, 30°, 45°, 60° | |

| Angle Tolerance | ± 5° | ||

| Deepness Tolerance | ± 0.20mm | ||

| V-Cut Angle | 20°, 30°, 45° | ||

| Board Thickness | 0.1-3.2mm | ||

| Residues Thickness | ± 0.025mm | ||

| Cell Paraposition Precision | ± 0.025mm | ||

| Tolerance of Out-shape Process | ± 0.1mm | ||

| Board Warp | Max Value | 0.7% | |

| Optical Plotting | Max Plotting Area | 66mm χ 558.8mm | |

| Precision | ± 0.01mm | ||

| Repetitive Precision | ± 0.005mm | ||

Testing Procedures For PCB Board

---We perform multiple quality assuring procedures before shipping out any PCB board. These include:

* Visual Inspection

* Flying probe

* Bed of nails

· * Impedance control

· * Solder-ability detection

* Digital metallograghic microscope

· *AOI (Automated Optical Inspection)

Detailed Terms for PCB Manufacturing---Technical requirement for PCB assembly:

* Professional Surface-mounting and Through-hole soldering Technology

* Various sizes like 1206, 0805, 0603 components SMT technology

* ICT(In Circuit Test), FCT(Functional Circuit Test) technology.

* PCB Assembly With UL, CE, FCC, RoHS Approval

* Nitrogen gas reflow soldering technology for SMT.

* High Standard SMT&Solder Assembly Line

* High density interconnected board placement technology capacity.

Delivery Time for PCB board

1) PCB production time: Sample: 3-4 days / mass production: Within 7 days

2) Component purchase: 2 days if all components is available in our domestic market.

3) PCB Assembly: Samples: Whthin 2 days / mass production: Within 5 days

++++++++++++++++++++++++++Quotation Requirement and Time:

1) Following specifications are needed for quotation:

A) Base material:

B) Board thickness:

C) Copper thickness:

D) Surface treatment:

E) color of solder mask and silkscreen:

F) Quantity

2) Qutoation within 2 hour after we get the gerber file or PCB file with complete specifications

Shipping Method and Payment terms:

1. By DHL, UPS, FedEx, TNT using clients account.

2. We suggest you using our DHL, UPS, FedEx, TNT forwarder.

3. By EMS (Usually for Russia Clients), price is high.

4. By sea for mass quantity according to customer's requirement.

5. By customer's Forwarder

6. By Paypal, T/T, West Union, etc.

You may also like

Send inquiry

Send now